↩ Back

Heavy construction profits from business aviation

Companies benefit in several ways

As CEO of Jomax Construction Co., Inc., a contractor specializing in cross-country pipeline construction, Max Nichols knows how to quickly identify his most formidable competitors in the heavy construction industry.

“The companies operating their own aircraft, those are the ones you’ve got to look out for.”Max Nichols, CEO, Jomax Construction Co., Inc.

Nichols knows because owning and flying an airplane has helped his team grow a modest oil field construction company formed by his parents in 1961 in Great Bend, Kansas, into a specialty contractor sought out by major natural gas and oil transmission companies for infrastructure projects throughout the Great Plains region of the U.S.

“We’ve had an airplane since the mid-1980s, and without a company-owned airplane, we could not do what we do – multiple construction projects in four or five different states at any one time and have 800+ employees during the construction season. Emphasis on ‘company-owned.’ The airplane is at our disposal whenever we need it without having to call and ask anybody,” he said.

70% of companies operating aircraft have fewer than 1,000 employees.

59% of companies operating aircraft have fewer than 500 employees.

Source: NBAA

Nichols isn’t alone; according to the National Business Aviation Association (NBAA), business aviation is considered an essential tool by 11,000 U.S.-based companies.

Jomax Construction Co., Inc. – Great Bend, Kansas

“When you live out in a remote area and you work in an even more remote area, commercial air travel just isn’t a viable alternative,” said Nichols, who flies the majority of Jomax’s 350-plus flight hours a year.

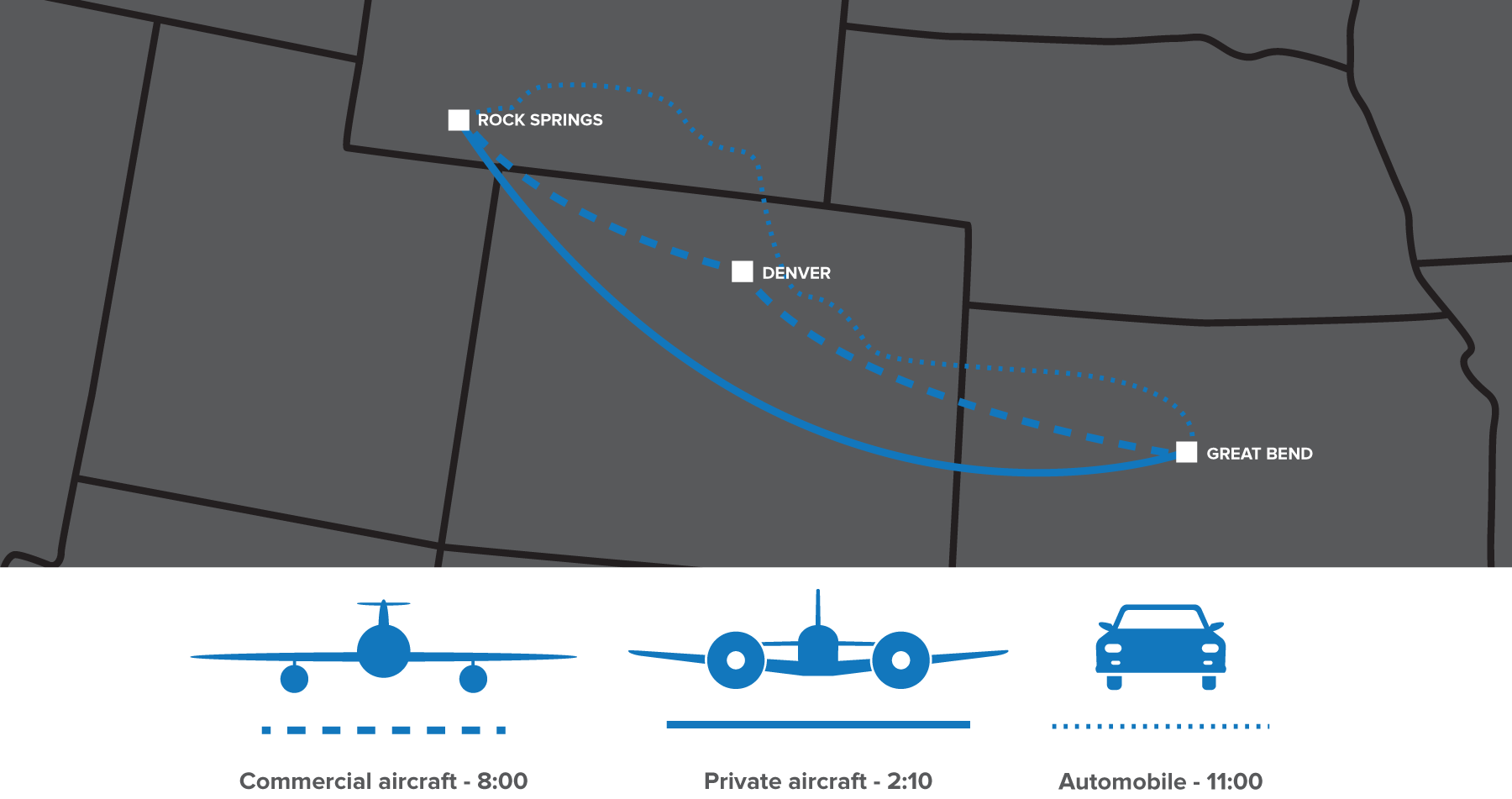

The company’s territory is roughly from the Mississippi River to the west side of the Rocky Mountains. The work is often in places like western Oklahoma, northeastern Colorado, southwestern Wyoming and western North Dakota. Airline service would rarely get Jomax management and technicians to their job sites.

Getting from Great Bend to Jomax’s warehouse in Rock Springs, Wyo., for example, is an 11- to 12-hour drive or a minimum of eight hours by airline. The company’s turboprop, a Beechcraft® King Air® 250, makes the flight from Great Bend to the warehouse in two hours and 10 minutes.

A regional carrier operates at Great Bend Municipal Airport, but Nichols said weather or maintenance delays create unreliable schedules.

“We need dependable transportation in order to deliver dependable service to our clients,” he said. “We work with clients who are very demanding, and we get a lot of their work because we are very responsive. We just couldn’t manage these jobs in outlying locations without a company-owned aircraft.”

10x as many airfields in the United States are available to general aviation than commercial aviation. This gets passengers closer to their final destinations.

Source: NBAA

Wilson Construction – Canby, Oregon

When Don Wilson joined the utility construction company his father founded, he drove 60,000 miles in Oregon and Washington in one year.

“I realized I wasn’t going to have any kind of home life if I kept driving for business, so I got my pilot’s license,” he said.

That was 1974, and today Wilson Construction operates a King Air C90GTx and King Air 350 for a combined 500 to 600 hours a year. The twin-engine turboprops have allowed the company to bid on jobs outside the Pacific Northwest and grow to have offices in Oregon, California and Arizona while employing 500 people across the U.S. supporting electrical transmission power projects.

All levels of employees travel on Wilson Construction’s airplanes and for a variety of reasons. Much of the company’s work is in remote areas, so the aircraft save time and money when dispatching crews and parts in emergency work situations or moving linemen between project sites or transporting management to bid on projects or attend on-site meetings.

Wilson said business aviation gives his company a competitive advantage in many ways, including minimizing non-business hours away from home for his employees and taking advantage of opportunities quicker.

“An airplane is a sign of a successful company in the eyes of customers,” he said. “Each time we have stepped up and bought a bigger or faster airplane, our business has increased. Having a more capable airplane enables us to reach out farther and become more flexible, and that flexibility helps us get more work.”

A thought shared by countless other heavy construction executives, technician and field crews who rely on business aircraft to meet demanding goals in a demanding industry.